FST JOURNAL

The UK Nuclear Fusion Programme

DOI: https://www.doi.org/10.53289/KHPJ3121

How the UK is making strides in fusion

Ian Chapman

Ian Chapman is the chief executive of the United Kingdom Atomic Energy Authority (UKAEA). He has progressed through a number of positions in the UK fusion programme, including Head of Tokamak Science in 2014 and Fusion Programme Manager in 2015. In October 2016 he became UKAEA’s Chief Executive Officer, succeeding Sir Steven Cowley.

Summary:

- After breaking world records with NIF, we have confidence in our predictions moving ahead to big experiments, like ITER.

- ITER produces a very significant net power gain and really demonstrates that fusion can be done on a commercial scale.

- The UK has a unique competence in fusion that you cannot find anywhere else.

- We are seeing collaboration with industry on the scale of 1000s of companies now involved in fusion.

- The next phase for fusion in the UK is the development of a prototype powerplant called STEP.

Fusion is not necessarily always mañana, mañana , forever away.

In 2022, the National Ignition Facility (NIF) in the US announced that they had achieved real fusion power with a net thermal gain; so you get more thermal power out than put in. That’s a huge step for fusion. We also have the Joint European Torus (JET) that we host here in the UK. This is the largest fusion facility in the world, where we have successfully broken our own world record a number of times over the last three years, setting a final world record of 69 mega joules over about five seconds.

The important part of those experiments were that they overlaid exactly what we predicted would happen. That means that we have confidence in our predictions as we move ahead, to big experiments, like ITER.

ITER

ITER is the largest scientific collaboration ever undertaken by humanity. It's a huge project in every sense, both in footprint, price, timescale, geopolitical complexity, and in my view, impact. If ITER works and produces a very significant net power gain, where we'll put 50 megawatts of thermal power in and produce 500 megawatts of fusion power outwards, that would really demonstrate that fusion can be done on a commercial scale.

ITER is now largely built and many of its components are ridiculously complicated. At the start of the project, we didn't have supply chains for the components, we didn't really think they could be built, but they now exist. There have been so many world firsts involved in that project which have led to a whole new industry and we are delighted to see big energy companies and engineering firms getting involved in ITER throughout.

Whilst it is a global project, UK companies have been heavily involved. 650 million pounds worth of contracts have come into the UK supply chain and UK companies lead the construction management as agent and as architect engineer.

There has been a complete change in the fusion landscape and we are now doing things at power plant scale. We are beginning to have the industrial competence to do that but we are no longer in ITER. We are no longer in the Euratom research and training programme and JET ceased operation at the end of last year, so it's a time of much change.

Where the UK stands out

However, we are very lucky that the UK genuinely has a unique competence in fusion that you cannot find anywhere else, and that's multifaceted: It starts with our national lab- the UK Atomic Energy Authority (UKAEA) which is the largest fusion organisation in the world at the moment, and a lot of that competence is born from JET, but we are also the first people to build a spherical tokamak and we think spherical tokamaks have a huge potential for minimising cost and maximising commercial viability of fusion power plants.

We have also developed competence in all the enabling technologies that you need for fusion. So be that the materials which have to withstand the unfavourable environment of the most intense neutron source on the planet and huge heat gradients, how you manufacture and test and qualify those materials, how you maintain the inside of the machine (which is a place you can't send people so you have to do robotically), or how you fuel the facility. We also have to make our own tritium. Tritium has a very short half-life and there's no natural tritium left so you have to make it. Understanding how you store, process and fuel machines with tritium is key.

Stitching all of that together needs complex and advanced computing. We do all of those things in the UK and that enables us to do the foundational things too. For example, we have really grown our supply base, we have invested heavily in skills and will continue to do so with government support. We're really thinking about technology transfer into fusion from other adjacent industries, and also out of fusion. We are also developing the competence to build power plants. At the same time, we are investing in industry programmes which develop small and medium sized enterprises, new technology and innovation in the sector. Startups like First Light Fusion and Tokamak Energy are being born in the UK which is really good to see.

Fusion really is all over the country. UKAEA as the national lab now has four sites, we have university partners in 35 different universities and we now have 4000 companies working in fusion.

The spherical tokamak

One of the big hindrances to the spherical tokamak is trying to make the powerplant as compact as possible. If you look at ITER, a third of the money goes in very large buildings. Another third goes on huge magnets with the largest cryogenics plant in the world to cool those magnets. So if you can use smaller more geometrically efficient magnets and put them in a much smaller building, you can strip out billions of cost.

After building the first spherical tokamak in the 90s, we showed it was far more efficient than alternative ways of approaching fusion. However, the condition for fusion is that the fuel has to be 100 million degrees or it won’t fuse. If you take that sort of heat source and put it into a much smaller volume, the chances of melting the walls of your box are obviously a lot higher. So the rest of the world never really invested in spherical tokamaks, because they said you’d never be able to cope with the heat. We agreed that if we couldn’t find a way of extracting the heat, it could be a dead end so we built a machine called MAST Upgrade, which was the first public project to win the Royal Academy of Engineering major projects prize.

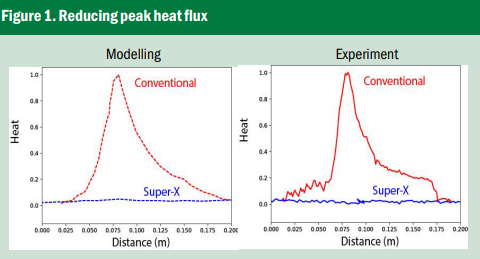

If you look at the first figure above, the red line is the conventional way of extracting heat from any magnetically confined fusion power plant. We said we think we can do it like the blue line here. So reduce the peak heat flux which gets to the wall by a factor of 10.

I don't think everybody in the community thought we would achieve that but when we turned on our facility in 2021, the second graph shows our first results. That really gave us confidence to move ahead with the spherical tokamak for energy production. Frankly, the UK is not big enough in the energy market to compete through volume. We will never have a product which becomes cheapest by building lots of units in the UK. We have to have a product which is innovative and therefore becomes cheaper than our competitors, and that's what we think the spherical tokamak offers.

What’s next for fusion energy in the UK?

Now in the concept design phase, we recently passed legislation and have found a site for development of a prototype powerplant called STEP. The main construction will likely happen over the 2030s and we are aiming to complete the build by around 2040. Based on all of the components needed to make this happen, this is simultaneously a depressingly long and audaciously fast timescale. The site chosen after a two year process with 15 nominations was, until March last year, a coal power station operated by EDF. It has a train line, a direct connection to a national grid, no new pylons, and an extraction licence of water from the Trent. It has millions of people living in the local environs less than an hour away and it has a population around it who have been involved in power generation their whole lives and want new power projects. This is the only fusion power plant project that actually has a site and is getting on with preparing that site. We are setting up a public private partnership in a slightly different way to many other countries in the world by both investing in innovation in SMEs, and at the same time working together with large companies on powerplant programmes. We have an industry programme, which is about stimulating innovation and working with SMEs. But we also have a national endeavour, which is about building a prototype power plant.

The first thing that we will do once we've set up this new company: ‘UK Industrial Fusion Solutions’, is to contract two partners. These will be an engineering partner and a construction partner, who will be with us on that 20 year journey to build a prototype. Our aspiration is that having done that, they then have the competence to build more power stations. This is a huge export potential for the UK as not just having a design of a power plant, but enabling the whole supply chain in the critical technologies which are required for fusion.

The last ingredient is people. We’re working very hard on training the next generation of people, and the government have invested heavily in apprentice training centres. Today, we have 460 learners for 35 different organisations and we want to do the same at not just apprentice level, but at graduate level, PhD level and postdoc level with a 55 million pound investment from the government to do that.

Not only has the UK seen some really big advances in the last couple of years, broken the world record for fusion power many times and set up new facilities across all of the enabling technologies needed for fusion, we are seeing collaboration with industry on the scale of 1000s of companies now involved in fusion. We hope that continues to increase, notably as we now procure partners to move forward with the STEP programme with us.